Actual Visit To LUYU Factory - Witnessing The Quality-Inspection2025-07-087We can further communicate and introduce LUYU's history, culture, product range, market distribution and commitment to quality.

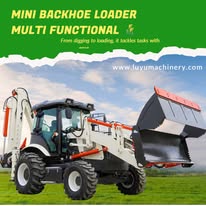

Actual Visit To LUYU Factory - Witnessing The Quality-Inspection2025-07-087We can further communicate and introduce LUYU's history, culture, product range, market distribution and commitment to quality. LUYU LY388A Backhoe Loader Excavator Upgrade On Line2025-07-022LUYU has done in-depth research on the product market and upgraded the production line of the backhoe loader according to the customer's demand.

LUYU LY388A Backhoe Loader Excavator Upgrade On Line2025-07-022LUYU has done in-depth research on the product market and upgraded the production line of the backhoe loader according to the customer's demand. How to choose the right electric forklift2025-07-011Forklift is an indispensable assistant in the warehouse and factory, and electric forklift is becoming more and more popular because of its environmental protection and low operating costs. But the major brands of electric forklifts are various, in the end how to choose?

How to choose the right electric forklift2025-07-011Forklift is an indispensable assistant in the warehouse and factory, and electric forklift is becoming more and more popular because of its environmental protection and low operating costs. But the major brands of electric forklifts are various, in the end how to choose? What can a 1 ton mini excavator do?2025-06-304LY10 has become a star model of the new generation of micro-hydraulic excavators by virtue of its hardcore strength of 'small stature, big energy'. Today, luyu will analyze the unique charm of this micro excavator from three dimensions: performance, comfort and applicability.

What can a 1 ton mini excavator do?2025-06-304LY10 has become a star model of the new generation of micro-hydraulic excavators by virtue of its hardcore strength of 'small stature, big energy'. Today, luyu will analyze the unique charm of this micro excavator from three dimensions: performance, comfort and applicability. About backhoe loader buckets2025-06-301The bucket is the common configuration of the backhoe loaders, and its selection is directly related to the use of the efficiency of the situation. Backhoe loaders can be configured with different buckets to accomplish different types of tasks.

About backhoe loader buckets2025-06-301The bucket is the common configuration of the backhoe loaders, and its selection is directly related to the use of the efficiency of the situation. Backhoe loaders can be configured with different buckets to accomplish different types of tasks. Backhoe loader shovel digging machine maintenance method2025-06-27Backhoe Loader Shovel Digger is a special type of loader with a loading bucket and a digging bucket that can load and dig materials at the same time. The following are the general maintenance methods for Backhoe Loader.

Backhoe loader shovel digging machine maintenance method2025-06-27Backhoe Loader Shovel Digger is a special type of loader with a loading bucket and a digging bucket that can load and dig materials at the same time. The following are the general maintenance methods for Backhoe Loader.

{item.title}

{item.add_time}

{item.description}

Send Your Inquiry